So after the mostly successful Copper Flogger, I decided to see how my experience would transfer over to a stainless steel tube.

The first problem I encountered was the Outside Diameter (OD) is smaller than the one on the copper tube. I ordered 1 inch OD but when the first one got was less than 1 inch. Figured they sent the wrong size, so I ordered another.

Second one came in and was the same size of the first. So I figured this was the industry standard and made adjustments. Already had some collars for the tube and put a chrome pull on the end. The final handle construction looks like this:

To go with the look I wanted, I decided get a black hide. Yak, this time to continue to exotic rhythm. Yak would also provide a heavier fall.

It took forever for the hide to show up here. Not so much because of the shipper, but the Post Office bounced it around NE Kansas for almost a week. But it finally arrived:

Now this stuff is much thicker and tougher than I had figured. Attempting to cut it with my exacto knife got me poor results, so I ordered new blades for my rotary cutter.

Titanium coated blades!

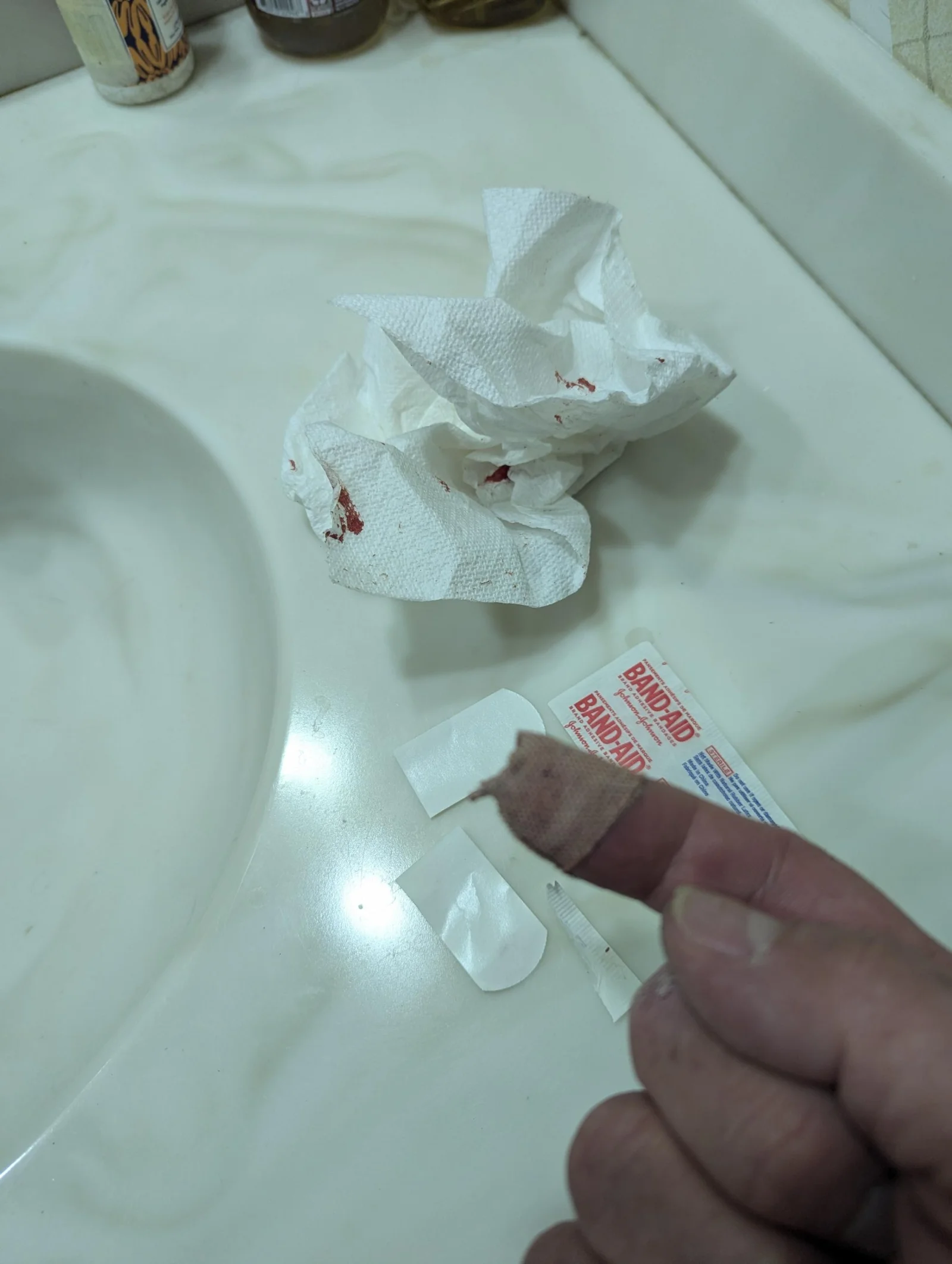

When those arrived, I was cleaning the packing oil off one of them and found out how sharp they were:

It was like I was in an SNL skit about Julia Childe

But was able to clean up and get back to business. My goal was to make it only 13 falls this time, figuring that the weight would make up for the thuddiness.

So the final problem came when the thicker falls went into the smaller tube, only 11 falls would squeeze in. So the flogger is sitting on the work bench til Thursday to let the glue cure and we will see how it all works out: